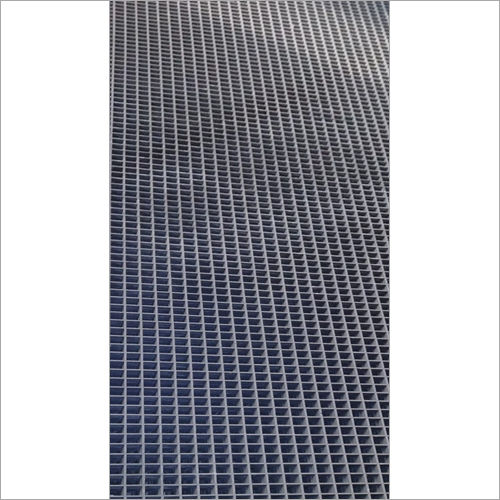

Drainage Cover FRP Grating

Product Details:

- Color Grey

- Usage Drainage

- Product Type Drainage Cover FRP Grating

- Material FRP

- Surface Treatment Painted

- Click to View more

Drainage Cover FRP Grating Price And Quantity

- 100 Piece

- 200 INR/Piece

Drainage Cover FRP Grating Product Specifications

- Painted

- FRP

- Drainage Cover FRP Grating

- Drainage

- Grey

Drainage Cover FRP Grating Trade Information

- 1000 Piece Per Day

- 10 Days

- All India

Product Description

Drainage Cover FRP Grating .

FRP (Fiber Reinforced Plastic) grating is a type of grating made from a composite material consisting of a polymer matrix reinforced with glass fibers. FRP grating is known for its corrosion resistance, lightweight nature, and high strength-to-weight ratio. It is commonly used in various industries, including wastewater treatment plants, chemical processing facilities, and other environments where traditional materials may corrode or degrade.

If you are looking for a drainage cover made of FRP grating, it is likely to be used in areas where drainage is essential, such as industrial floors, platforms, or walkways. The use of FRP grating for drainage covers offers several advantages, including:

Corrosion Resistance: FRP is highly resistant to corrosion, making it suitable for environments where exposure to chemicals or moisture is a concern.

Lightweight: FRP grating is lightweight compared to traditional materials like steel, making it easier to handle during installation.

High Strength: Despite being lightweight, FRP grating has a high strength-to-weight ratio, providing structural integrity while supporting heavy loads.

Durability: FRP grating is durable and can withstand harsh environmental conditions, including exposure to UV radiation.

Non-Conductive: FRP is a non-conductive material, making it suitable for use in electrical environments where conductivity is a concern.

Low Maintenance: FRP grating requires minimal maintenance and is easy to clean, contributing to its cost-effectiveness over time.

When selecting an FRP grating for a drainage cover, consider factors such as the mesh size, load-bearing capacity, and the specific requirements of the environment in which it will be installed. Additionally, FRP grating can be customized to meet specific design and size requirements.

It's important to consult with the manufacturer or supplier to ensure that the chosen FRP grating meets the necessary specifications for your drainage cover application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+