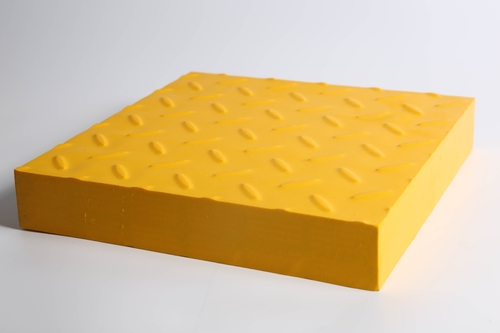

FRP Chequered Plate Surface

500 INR/Piece

Product Details:

- Usage Industrial,

- Product Type FRP Chequered Plate Surface

- Color Yellow

- Material FRP

- Surface Treatment Polishing

- Size 38mm X 38mm

- Click to View more

X

FRP Chequered Plate Surface Price And Quantity

- 100 Piece

- 500 INR/Piece

FRP Chequered Plate Surface Product Specifications

- FRP Chequered Plate Surface

- Yellow

- FRP

- Industrial

- 38mm X 38mm

- Polishing

FRP Chequered Plate Surface Trade Information

- 1000 Piece Per Week

- 10 Days

Product Description

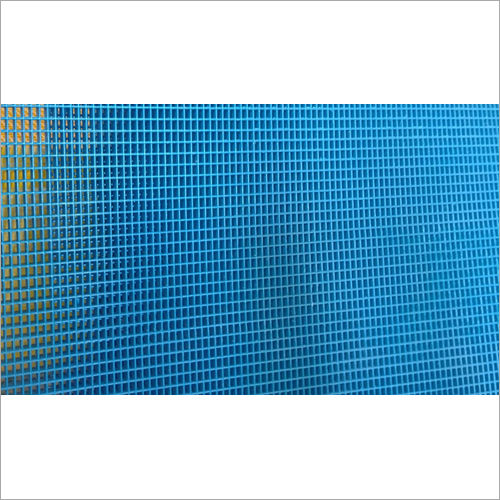

A chequered or checkered pattern on a Fiber Reinforced Plastic (FRP) plate surface serves the purpose of providing anti-slip properties. The pattern typically consists of raised or indented areas in a grid or diamond shape, creating a textured surface. This design is especially important in areas where slip resistance is a priority, such as industrial floors, walkways, or platforms. The chequered pattern helps improve traction and reduces the risk of slips and falls, making it safer for pedestrians and workers.

The specific design of the chequered pattern can vary, and it often depends on the manufacturer's specifications or the application requirements. Common patterns include:

Diamond Pattern: This is a classic design where the raised or indented areas form a diamond shape. It provides good slip resistance and is widely used in industrial settings.

Square Pattern: Similar to the diamond pattern but with squares instead of diamonds, this design also offers effective slip resistance.

Rectangular Pattern: In this design, the raised or indented areas form rectangles. It provides a different aesthetic while maintaining slip resistance.

Custom Patterns: Manufacturers may offer custom patterns based on specific project requirements or aesthetic preferences.

When considering an FRP chequered plate surface, it's essential to ensure that the pattern chosen meets the safety requirements of the intended application. Additionally, factors such as the size and depth of the chequered pattern, along with the overall thickness and composition of the FRP plate, can influence its performance in terms of durability and load-bearing capacity.

Consulting with the manufacturer or supplier is crucial to selecting an FRP chequered plate surface that aligns with the safety standards, environmental conditions, and load requirements of the specific project or application. Keep in mind that proper installation and regular maintenance are also important for ensuring the ongoing effectiveness of the anti-slip surface.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email