FRP Gratings For Oil and Gas Plant

FRP Gratings For Oil and Gas Plant Specification

- Shape

- Rectangle

- Usage

- OIL AND GAS PLANT

- Material

- Fiberglass

- Application

- OIL AND GAS PLANT

- Product Type

- GRATING

- Color

- YELLOW

FRP Gratings For Oil and Gas Plant Trade Information

- Minimum Order Quantity

- 50 Square Meters

- FOB Port

- VADODARA

- Supply Ability

- 10000 Square Meters Per Week

- Delivery Time

- 10 Days

- Packaging Details

- STANDARD PACKING

- Main Domestic Market

- All India

- Certifications

- na

About FRP Gratings For Oil and Gas Plant

Fiber Reinforced Plastic (FRP) gratings are commonly used in the oil and gas industry due to their corrosion resistance, durability, and other favorable properties. When considering FRP gratings for oil and gas plants, it's essential to focus on factors such as resistance to harsh chemicals, safety, and the ability to withstand heavy loads. Here are key considerations:Corrosion Resistance: FRP gratings are highly corrosion-resistant, making them suitable for environments where exposure to corrosive substances, including various chemicals found in the oil and gas industry, is common.

Chemical Resistance: FRP is resistant to a wide range of chemicals, ensuring that the grating maintains its structural integrity when exposed to different chemicals used in oil and gas processing.

Fire Resistance: Depending on safety regulations and plant specifications, consider FRP gratings with fire-resistant properties for increased safety in oil and gas facilities.

Anti-Slip Properties: Oil and gas plants may involve the presence of liquids and slippery surfaces. Choose FRP gratings with an anti-slip surface to enhance safety for workers in such areas.

High Load-Bearing Capacity: Oil and gas plants often have heavy equipment and machinery. Ensure that the FRP gratings have the appropriate load-bearing capacity to support the expected loads.

Non-Conductive: FRP is a non-conductive material, making it safe for use in electrical environments. This is important in oil and gas facilities where electrical components may be present.

UV Resistance: If outdoor installations are involved, choose FRP gratings that are UV resistant to withstand prolonged exposure to sunlight.

Customization: FRP gratings can be customized to fit specific design requirements, including size, mesh configuration, and color. This allows for flexibility in meeting the unique needs of oil and gas facilities.

Low Maintenance: FRP gratings generally require minimal maintenance. Regular cleaning is often sufficient to keep them in good condition, contributing to long-term cost savings.

Durability: FRP gratings are durable and resistant to impact, making them suitable for areas where heavy equipment or foot traffic may cause wear and tear.

Resistance to Flammable Substances: Given the nature of the oil and gas industry, ensure that the FRP gratings are resistant to flammable substances and are designed to minimize the risk of ignition.

When selecting FRP gratings for oil and gas plants, it's crucial to work closely with the manufacturer or supplier. They can provide guidance on the specific type of FRP grating that best suits the chemical exposure conditions, load requirements, and safety considerations of the plant. Compliance with relevant industry standards and regulations should also be considered during the selection process. Regular inspections and maintenance are important to ensure the continued effectiveness and safety of the FRP gratings in oil and gas applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FRP Gratings Category

Fiberglass grating

Price 360.0 INR / Unit

Minimum Order Quantity : 100 Units

Usage : Industrial , Swimming Pool , Floor , Walkway

Surface Treatment : Polishing

Color : Yellow , Green , Red

Material : Fiberglass

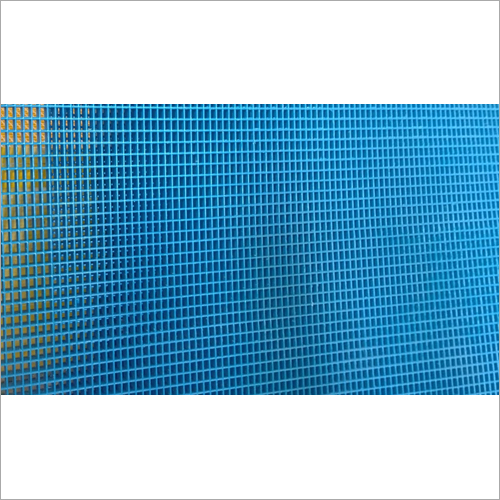

Paint Coated Blue FRP Gratings

Price 9600 INR / Piece

Minimum Order Quantity : 5 Pieces

Usage : Industrial

Surface Treatment : Painted

Color : Blue

Material : FRP

FRP GRP GRATING

Price 1200 INR / Meter

Minimum Order Quantity : 200 Meters

Usage : Industrial

Surface Treatment : Powder Coated

Color : Black & Yellow

Material : FRP

FRP Gratings For Marine Industreis

Price 500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Usage : Industrial

Surface Treatment : Painted

Color : Grey

Material : FRP