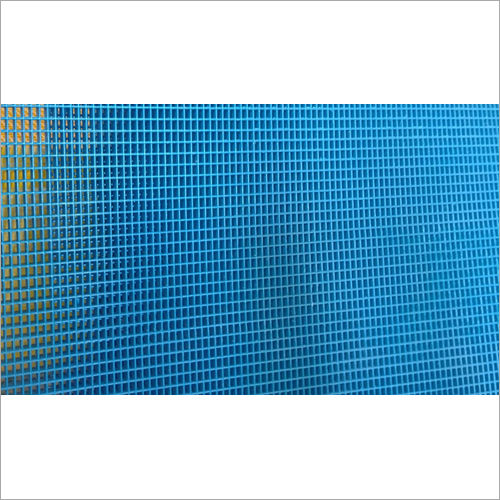

FRP Gratings For Chemical Plant

500 INR/Piece

Product Details:

- Usage Industrial

- Product Type FRP Gratings For Chemical Plant

- Material FRP

- Surface Treatment Painted

- Click to View more

X

FRP Gratings For Chemical Plant Price And Quantity

- 100 Piece

- 500 INR/Piece

FRP Gratings For Chemical Plant Product Specifications

- FRP Gratings For Chemical Plant

- FRP

- Industrial

- Painted

FRP Gratings For Chemical Plant Trade Information

- 1000 Piece Per Week

- 7 Days

- All India

Product Description

Using FRP (Fiber Reinforced Plastic) grating in a chemical plant offers several advantages due to its unique properties. Here are some considerations when choosing FRP grating for a chemical plant:Corrosion Resistance: Chemical plants often have harsh environments with exposure to corrosive substances. FRP grating is highly resistant to corrosion, making it an excellent choice for areas where traditional materials, such as steel, might corrode.

Chemical Resistance: FRP is resistant to a wide range of chemicals, acids, and bases. This makes it suitable for use in chemical processing areas where exposure to various corrosive substances is common.

Lightweight Design: FRP grating is lightweight compared to materials like steel. This can simplify installation and reduce the load on supporting structures.

High Strength: Despite its lightweight nature, FRP grating has a high strength-to-weight ratio, allowing it to support heavy loads. This is important in industrial settings where equipment and machinery may be placed on grating surfaces.

Non-Conductive: FRP is a non-conductive material, making it safe for use in electrical environments. This is crucial in chemical plants where electrical conductivity can pose a hazard.

UV Resistance: FRP is resistant to ultraviolet (UV) radiation, making it suitable for outdoor applications. If the chemical plant involves outdoor areas, UV resistance becomes an important factor.

Low Maintenance: FRP grating requires minimal maintenance, which can be advantageous in busy industrial settings. Routine cleaning is often sufficient to keep FRP grating in good condition.

Customization: FRP grating can be customized to meet specific design requirements, including size, mesh configuration, and color. This flexibility allows for tailored solutions based on the needs of the chemical plant.

Fire Resistance: FRP grating can be formulated to be fire-resistant, which is an important consideration in chemical plants where fire safety is a priority.

When selecting FRP grating for a chemical plant, it's crucial to work closely with the manufacturer or supplier. They can provide guidance on the specific type of FRP grating that best suits the chemical exposure conditions, load requirements, and other factors unique to the plant. Compliance with relevant industry standards and regulations should also be considered during the selection process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email