FRP Gratings for Civil Site

500 INR/Piece

Product Details:

- Usage For Solar Panel Rooftop Area

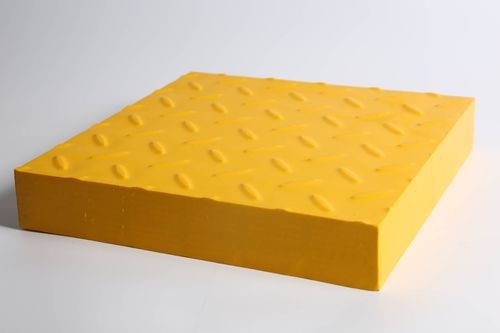

- Color Yellow

- Shape Rectangle

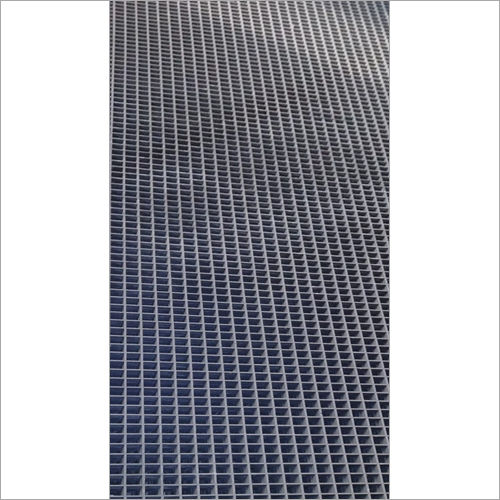

- Product Type FRP Gratings

- Material FRP

- Surface Treatment Painted

- Size 310x3660 mm

- Click to View more

X

FRP Gratings for Civil Site Price And Quantity

- 1000 Piece

- 500 INR/Piece

FRP Gratings for Civil Site Product Specifications

- FRP

- Rectangle

- Painted

- For Solar Panel Rooftop Area

- 310x3660 mm

- FRP Gratings

- Yellow

FRP Gratings for Civil Site Trade Information

- 1000 Piece Per Week

- 5 Days

- All India

Product Description

Fiber Reinforced Plastic (FRP) gratings are commonly used in civil engineering and construction sites due to their versatility and durability. Here are some considerations when using FRP gratings for civil sites:Load-Bearing Capacity: Civil sites often involve heavy equipment, vehicles, and foot traffic. Ensure that the FRP gratings selected have the appropriate load-bearing capacity to support the expected loads.

Corrosion Resistance: FRP gratings are highly resistant to corrosion, making them suitable for civil sites where exposure to moisture, chemicals, and environmental elements is common.

Lightweight Design: FRP gratings are lightweight compared to traditional materials like steel. This characteristic makes them easier to handle, transport, and install on civil construction sites.

Anti-Slip Surface: Choose FRP gratings with an anti-slip surface to enhance safety, especially in areas where workers or vehicles may encounter wet or slippery conditions.

Chemical Resistance: Civil sites may involve exposure to various chemicals, including those used in construction materials. Ensure that the FRP gratings are resistant to these chemicals to maintain their structural integrity over time.

UV Resistance: If the FRP gratings will be exposed to sunlight, select products that are UV resistant to prevent degradation and maintain their appearance and performance.

Customization: FRP gratings can be customized to fit specific dimensions and requirements of the civil site. Ensure that the chosen gratings can be tailored to the needs of the project.

Ease of Installation: FRP gratings are known for their ease of installation. Confirm that the gratings can be installed efficiently and securely, potentially reducing labor costs and installation time.

Low Maintenance: FRP gratings generally require minimal maintenance. Regular cleaning may be sufficient to keep them in good condition, contributing to long-term cost savings.

Non-Conductive Properties: FRP is non-conductive, making it suitable for use in areas where electrical conductivity may be a concern, such as near electrical installations or during construction activities involving electrical work.

Durability: FRP gratings are durable and resistant to impact. This durability is essential in civil sites where construction materials, heavy machinery, and other factors may subject the gratings to wear and tear.

Fire Resistance: Depending on local regulations and project specifications, consider FRP gratings with fire-resistant properties for increased safety.

When selecting FRP gratings for civil sites, it's important to consult with the manufacturer or supplier to ensure that the chosen gratings meet the specific requirements of the project and comply with relevant industry standards and regulations. Regular inspections and maintenance should be conducted to ensure the continued effectiveness and safety of the FRP gratings in the civil site.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email