INDUSTRIAL FIBER GLASS GRATING

Product Details:

INDUSTRIAL FIBER GLASS GRATING Price And Quantity

- 1000 Meter

- 1000 INR/Meter

INDUSTRIAL FIBER GLASS GRATING Trade Information

- VADODARA

- All India

Product Description

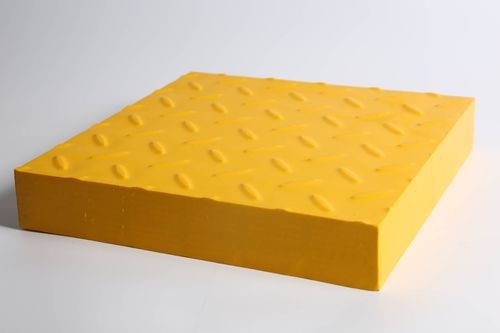

INDUSTRIAL FIBER GLASS GRATING

Industrial Fiberglass Grating: Benefits and Applications

Industrial fiberglass grating, made from fiberglass reinforced plastic (FRP), offers significant advantages across various industries. Here are key points to consider:

1. Corrosion Resistance

Fiberglass grating excels in harsh environments, resisting corrosion from chemicals and moisture. It's perfect for industries such as chemical processing and marine applications.

2. Lightweight and Easy to Handle

This grating is notably lighter than steel, reducing transportation costs and making installation easier without compromising strength.

3. Strength and Durability

Despite its lightweight nature, fiberglass grating is robust and durable, capable of withstanding heavy loads and impact.

4. Non-Conductive and Safe

It's non-conductive and doesn't conduct electricity, ensuring safety in environments with electrical equipment.

5. Low Maintenance

Requires minimal upkeep compared to materials like steel, as it doesn't rust or corrode.

6. Slip Resistance

Textured surfaces provide excellent slip resistance, even when wet, ensuring safety in industrial settings.

7. Fire Retardant Properties

FRP materials used are inherently fire retardant, meeting stringent safety standards.

8. Versatility in Applications

Available in various sizes, colors, and configurations to suit specific industrial needs, including oil and gas, pulp and paper, and food processing.

Why Choose Fiberglass Grating?

Fiberglass grating combines durability, safety, and versatility, making it an ideal choice for industries requiring reliable, long-lasting structural solutions.

For more information on how fiberglass grating can benefit your industry, contact us today.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+